|

|

|

Singlecut semi-hollowbody electric #015 | |

|

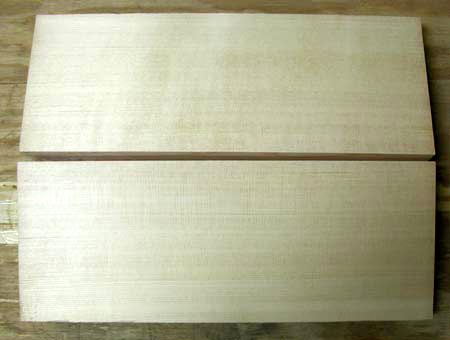

Sitka spruce. | |

| |

|

Lacewood. | |

| |

|

The top glued and ready to start carving the arch. | |

| |

|

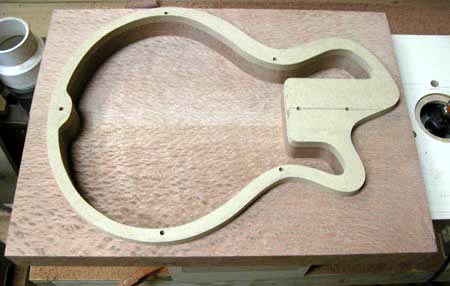

The body has been routed with a template to remove the mass of material that makes this a semi-hollow. | |

| |

|

The same template will serve to route the perimeter. | |

| |

|

The body completely routed. | |

| |

|

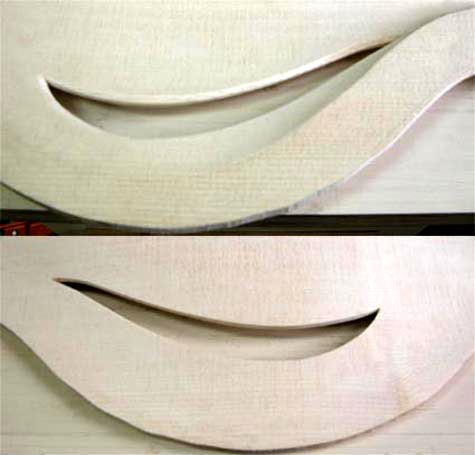

The top carved. | |

| |

|

Straight edges are placed over the top to show the arch better. | |

| |

|

Roughing out the inside arch. | |

| |

|

Inside carve complete. | |

| |

|

Body and top so far. Ready for bracing. | |

| |

|

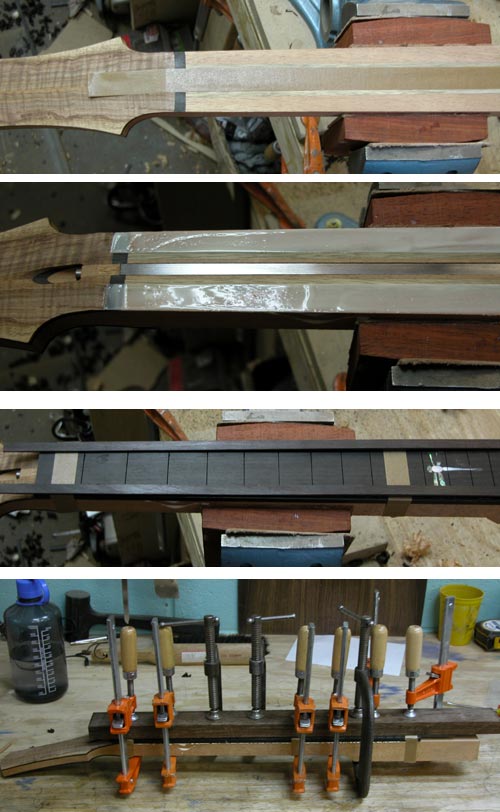

Braces are carved for an exact fit. No slop is tolerated for the braces. | |

| |

|

Braces are glued into place. | |

| |

|

Bracing complete. The brace ends will be locked into place when glued to the body. | |

| |

|

The headplate veneers are glued onto the front and back of the headstock. | |

| |

|

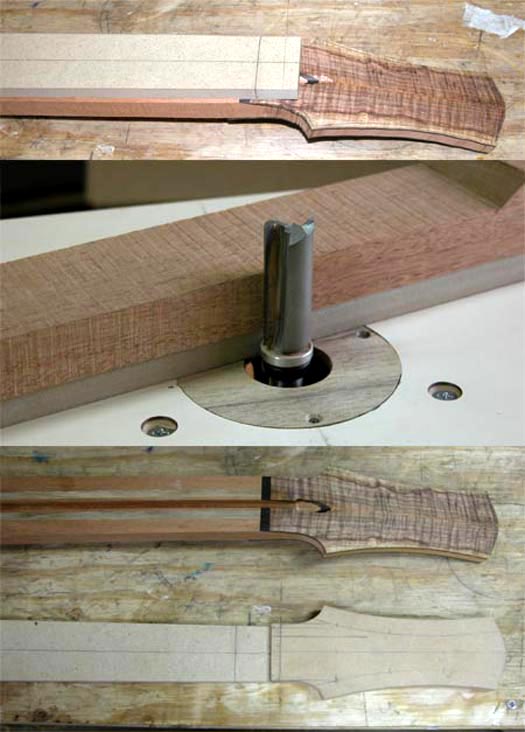

Neck taper and headstock shape are routed next. | |

| |

|

Single top sound hole is sawed out with a coping saw. | |

| |

|

The soundhole is smoothed and shaped with a razor and files. | |

| |

|

Soundhole complete. | |

| |

|

The top glued onto the body. Sweet!~ | |

| |

|

The recurve is starting to be carved. | |

| |

|

The tailpiece in place to show how the guitar will look. | |

| |

|

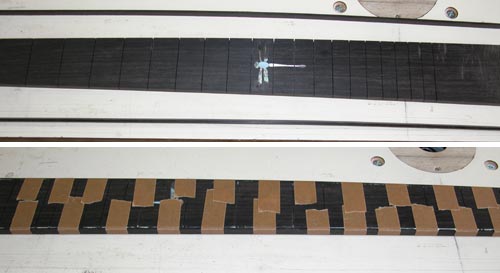

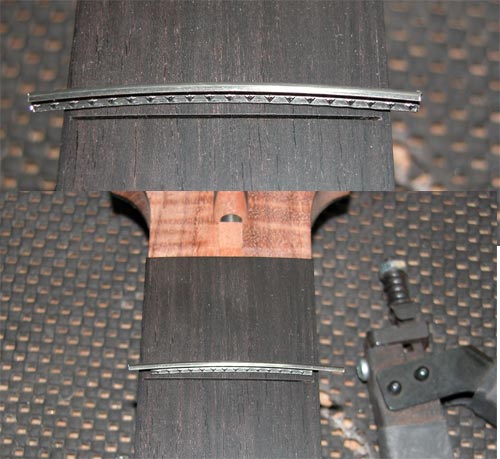

The binding is cut and taped into place after the inlay is completed. | |

| |

|

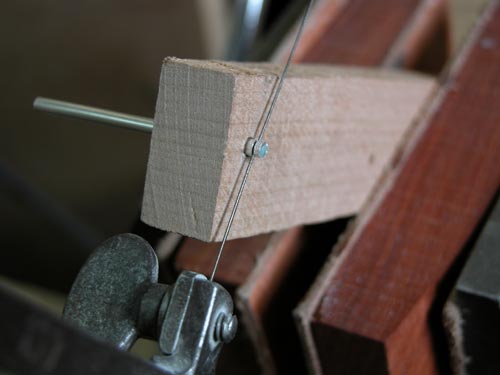

The truss rod is filed round on the ends so that it fits into the round bottom slot. | |

| |

|

The fingerboard is glued on. The tape over the truss rod prevent too much glue | |

| |

|

Once glued the fingerboard is routed to fit using the neck as a template on the router table. | |

| |

|

Here is a close up of the dragonfly inlay. | |

| |

|

The next few photos show how I do the side dot markers. I use a shell dot, in this case Paua, and tubing to surround it. I used silver. First the holes are drilled. | |

| |

|

For each dot the silver tubing is cleared and filed to fit the slightly oversized shell dot. | |

| |

|

The tubing is pressed over the dot and tapped into place with a small hammer. | |

| |

|

The dot is in place. | |

| |

|

The tubing is cut the length of the dot material thickness. | |

| |

|

The dot ready to glue. | |

| |

|

The dot complete and ready to sand flush. | |

| |

|

The bridge blank is scribed along the arched top. | |

| |

|

It is then cut on a bandsaw and filed to shape. | |

| |

|

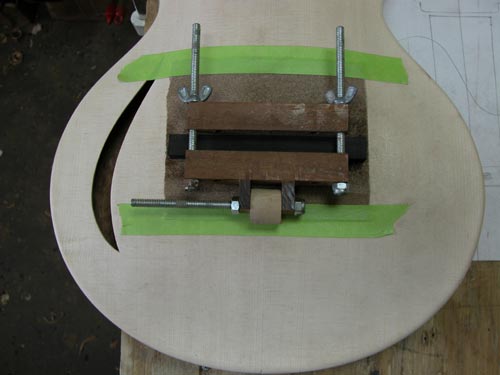

I made this jig from the Benedetto book to sand the bridge bottom on the arched top. | |

| |

|

The jig in action. | |

| |

|

Perfect fit! | |

| |

|

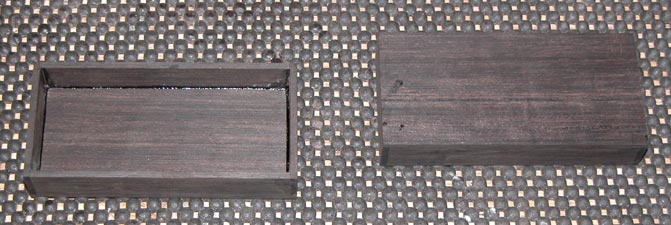

The bridge pieces: | |

| |

|

The bone saddle. This is going to have a bone nut as well. It should have a great acoustic tone. | |

| |

|

The outline of the bone is scribed onto the ebony piece with an awl. | |

| |

|

Chalk is rubbed into the outline to give us a line to work with. | |

| |

|

The ebony is taped to the table and 2 rails hold the router to height. The outline is routed to 3/16". | |

| |

|

There is a little slop in the cut. | |

| |

|

A mixture of epoxy and ebony wood dust is prepared. | |

| |

|

After wetting the slot with just epoxy the mixture is pressed into the slot. | |

| |

|

The bone saddle is waxed heavily and pressed into the slot and clamped until cured. | |

| |

|

With just the saddle in a vise hit the ebony with a small hammer to realease. | |

| |

|

Another perfect fit! Works great on acoustic guitar bridges too. | |

| |

|

Next the thumbscrew holes are drilled. | |

| |

|

Thumbscrews are in place. | |

| |

|

The bridge is ready for final shaping and carving. | |

| |

|

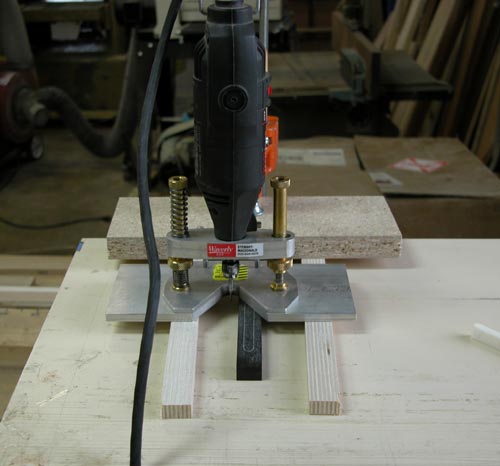

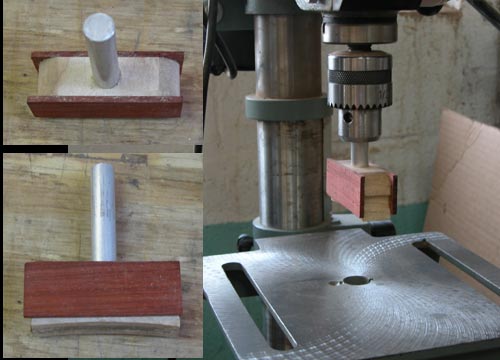

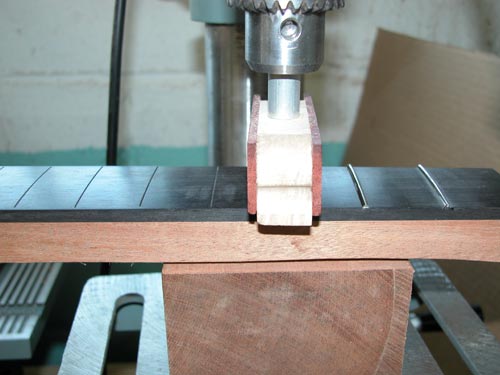

Here is a pic of my homemade fret press. I cut off an end of a Stew Mac radius sanding block and put a dowel in it to fit onto a drill press. | |

| |

|

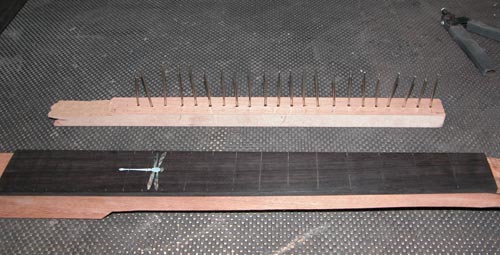

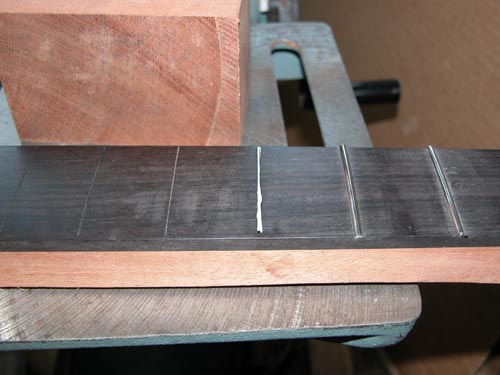

Here is a pic showing the fret being cut to size and the end overhang cut to fit over the binding. | |

| |

|

All the frets ready to go. | |

| |

|

First run a tiny bead of Titebond glue into the slot. | |

| |

|

Then fit the fret in place. Use a small hammer if you need to tap it in a bit. | |

| |

|

Then press it in with the fret press. Make sure it seats well. | |

| |

|

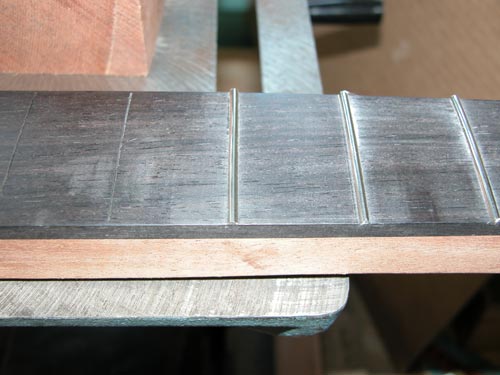

The fret cleaned of glue and the ends trimmed. | |

| |

|

The whole neck fretted. | |

| |

|

The final step involves putting one drop of gap filling super glue on every fret end. This keeps strings from getting underneath them. | |

| |

|

This setup is for routing the neck pocket. The guitar is clamped into place and the neck is clamped onto the straight edges. | |

| |

|

Next a back stop is clamped into place and two layers of tape are put on the stright edges. For the final pass the tape is removed. | |

| |

|

Nice tight fit! | |

| |

|

Here is a shot from the front. | |

| |

|

Top view. | |

| |

|

The neck roughed carved. | |

| |

|

Back view of the neck glued in place. That lacewood looks nice! | |

| |

|

Top view of the neck in clamps. | |

| |

|

Tailpiece slotted for the hinge. | |

| |

|

Hinge detail | |

| |

|

Complete. The rod is steel and the hole will be filled. | |

| |

|

The guitar ready for lacquer. A coat of blonde shellac has been applied to give it that amber tone. | |

| |

|

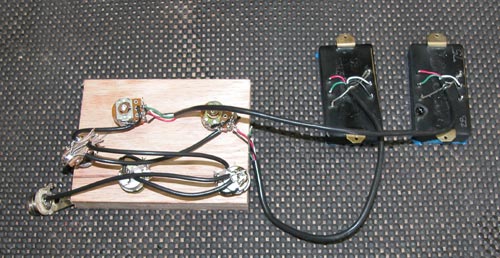

The wiring harness. | |

| |

|

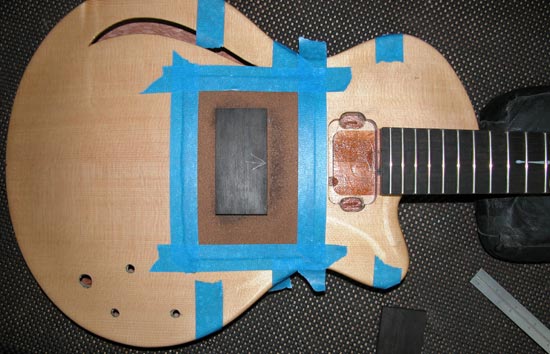

Ebony pickup rings. These are made with 1/8" thick pieces. First the ring is glued together and then a top piece is fitted. The holes will be routed nad drilled after shaping. | |

| |

|

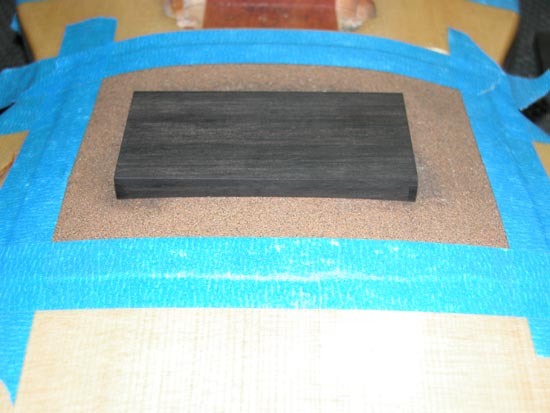

Sandpaper is taped to the guitar body to sand the covers to fit the curve exactly. | |

| |

|

Fit to the curve. | |

| |

|

|

|

|

|